-

Thanh toán đa dạng, linh hoạtChuyển khoản ngân hàng, thanh toán tại nhà...

Thanh toán đa dạng, linh hoạtChuyển khoản ngân hàng, thanh toán tại nhà... -

Miễn Phí vận chuyển 53 tỉnh thànhMiễn phí vận chuyển đối với đơn hàng trên 1 triệu

Miễn Phí vận chuyển 53 tỉnh thànhMiễn phí vận chuyển đối với đơn hàng trên 1 triệu -

Yên Tâm mua sắmHoàn tiền trong vòng 7 ngày...

Yên Tâm mua sắmHoàn tiền trong vòng 7 ngày...

The Preparatory Manual of Black Powder and Pyrotechnics version 4.0 Volume 1: Methods of forming pyrotechnic compositions I

-

- Mã sản phẩm: 1980538271

- (71 nhận xét)

- Publisher:Independently published (March 11, 2018)

- Language:English

- Paperback:374 pages

- ISBN-10:1980538271

- ISBN-13:978-1980538271

- Item Weight:2.15 pounds

- Dimensions:8.5 x 0.85 x 11 inches

- Best Sellers Rank:#750,351 in Books (See Top 100 in Books) #252 in Scientific Reference #2,515 in Technology (Books)

- Customer Reviews:4.5 out of 5 stars 71Reviews

Mô tả sản phẩm

From the Publisher

6a. Methods of forming pyrotechnic compositions

In some cases, the desired pyrotechnic composition can be readily formed by simply blending the ingredients together using any desired means. However, sometimes pyrotechnic compositions can only be formed when they are mixed in special ways. Black powder for example, cannot simply be made by just blending the ingredients together. To form black powder and similar pyrotechnic mixtures, the ingredients of the mixtures need to be blended very thoroughly to form a uniform mix; solvents are also widely used to facilitate proper blending to maximize surface area. To mix these ingredients very thoroughly requires special mixing devices. There are two main types of mixing apparatus available. The most common is the “ball mill”, and “vertical mixer”. A ball mill is a simple device utilizing a central container, similar to an empty coffee can laying on its side, and a small electric motor. The electric motor rotates the coffee can utilizing a fan belt or similar band. The rotating speed can very from 50 to 1500 RPM, depending on the type of mixing desired. In some cases, steel balls, or other materials are added to the mill, so they produce a high surface area of blending and pulverizing when the can rotates. Ball mills are one of the most common apparatus used to form pyrotechnic compositions, such as black powder. Also, as mentioned, in other cases, an inert solvent is added to facilitate proper pulverization and coheasion with maximum surface area. The second most common type of mixer is a vertical mixer. There are two types of “vertical mixers”; a) a common blender, as found in your kitchen, using stainless steel blades, and b) a large capacity “vertical mixer” utilizing plastic or stainless steel pallet blades that rotate widely and at a uniform speed; similar to a bread blender you might have in your home. All ingredients are added when necessary, and the mixture can be dry blended, or “wet” blended using an inert solvent to facilitate maximum surface area. Now, these two types of mixers may have different names, but their method of work is the same. You can find out more about these mixing devices by conducting a search on the Internet.

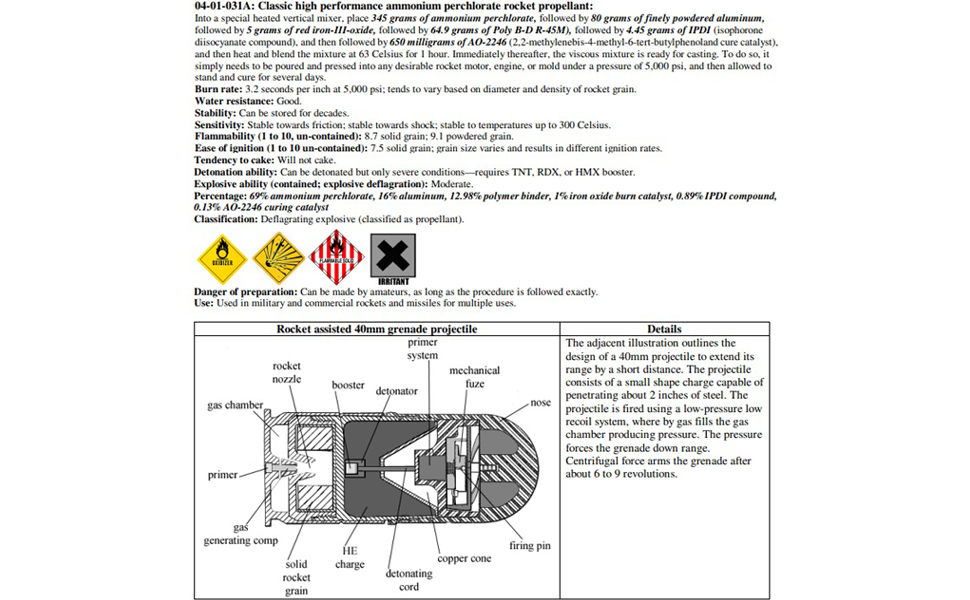

04-01-031A: Classic high performance ammonium perchlorate rocket propellant:

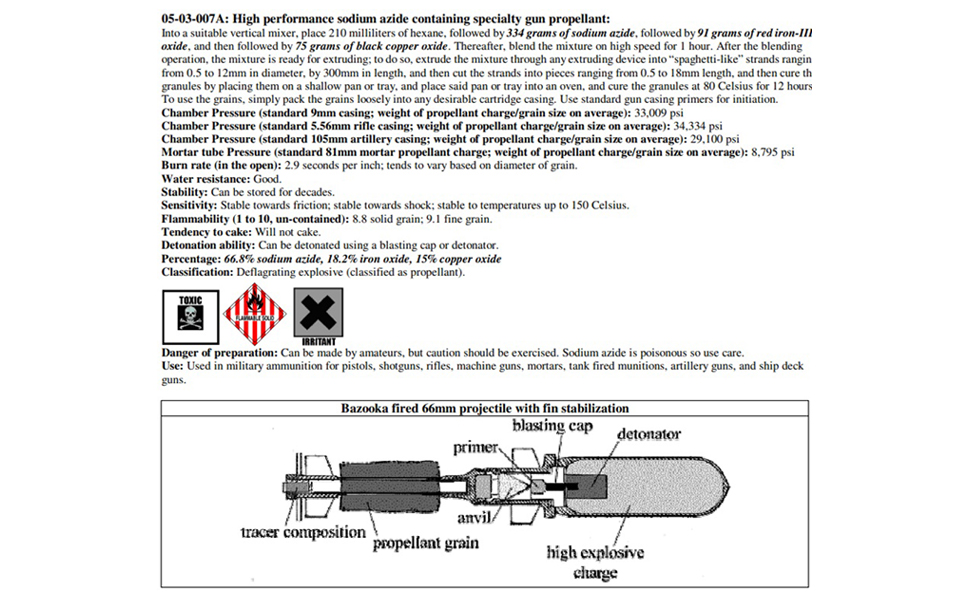

05-03-007A: High performance sodium azide containing specialty gun propellant:

06-01-006A: Blue tracer composition with gray smoke trail:

06-01-007A: High visibility tracer composition:

Into a standard ball mill, filled with 500 grams of Teflon coated steel shot of 10mm diameter, place 140 grams of calcium resinate, followed by 60 grams of standard powdered aluminum, followed by 170 grams of standard powdered magnesium, followed by 50 grams of strontium oxalate, followed by 500 grams of strontium nitrate, followed by 40 grams of sodium nitrate, followed by 50 grams of mercurous chloride. Thereafter, rotate the mixture at 170 RPM for 5 hours. After 5 hours, remove the mixture from the ball mill, and then separate the mixture from the steel shot in the usual manner. Thereafter, the mixture is ready for pressing. To do so, press the mixture into the tracer compartment of the given projectile under a pressure of 10,000 psi. Burn rate (tracer burn out, standard 40mm grenade round on average): 50 meters Burn rate (tracer burn out, standard 7.62mm rifle bullet on average): 300 meters Burn rate (tracer burn out, standard 7.62mm machine gun round on average): 600 meters Burn rate (tracer burn out, standard 12.7mm rifle bullet on average): 1200 meters Burn rate (tracer burn out, standard 25mm cannon round on average): 1050 meters Burn rate (tracer burn out, standard 105mm tank fired projectile on average): 1900 meters Water resistance: Good. Stability: Can be stored for many years. Flammability (1 to 10): 4.2 (pressed at 10,000 psi); 5 powdered. Ease of ignition (1 to 10): 4 (pressed at 10,000 psi); 7.9 powdered. Tendency to cake: None. Explosive ability: Cannot be detonated. Percentage: 49.5% strontium nitrate, 16.8% magnesium, 13.8% calcium resinate, 5.9% aluminum, 4.9% strontium oxalate, 4.9% mercurous chloride, 3.9% sodium nitrate, 0.30% residue Classification: Deflagrating mixture (classified as 1.3G pyrotechnic composition).

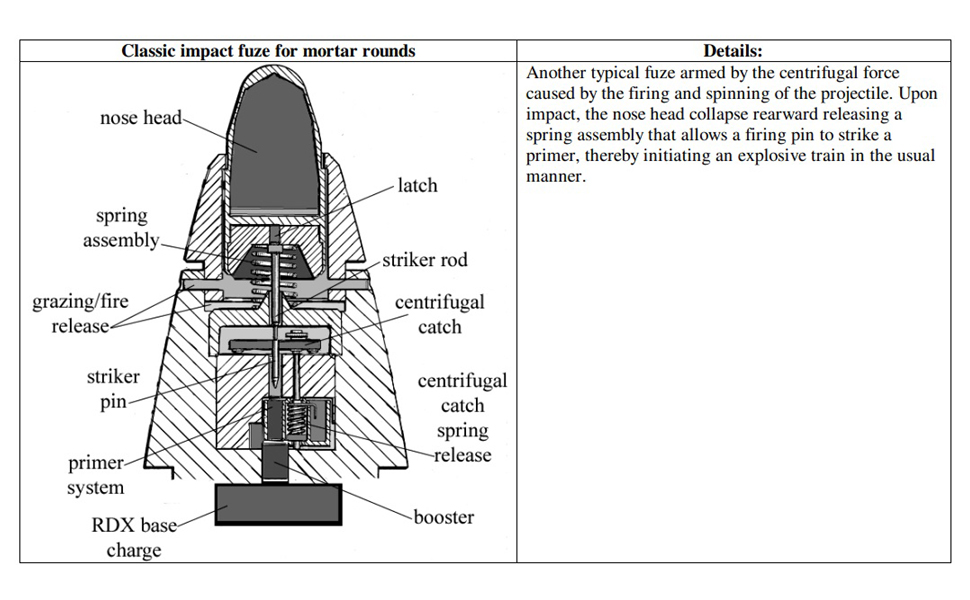

06-04-045B: Classic highly insensitive ignition composition for use in moderately accelerating projectiles such as mortar rounds:

Into a standard ball mill, filled with 500 grams of steel shot of 10mm diameter, place 350 grams of finely ground magnesium powder of average mesh, followed by 75 grams of potassium perchlorate, followed by 37.5 grams of silicon dioxide and then followed by 37.5 grams of polybutadiene. Thereafter, tumble the mixture at room temperature at 260 RPM for about 45 minutes. Thereafter, the mixture should be removed from the ball mill, and the steel shot separated; thereafter, the mixture is ready for pressing. To do so, press the mixture into blocks, discs, or tablets under a pressure of 2,500 psi. Burn rate: 19 seconds per inch at 2,500 psi; tends to vary based on diameter and density of grain. Burn temperature: 1,260 Celsius. Ignition temperature (average temperature to ignite mixture): 955~ Celsius. Water resistance: Very good. Stability: Can be stored for many years. Flammability (pressed grain at 2,500 psi): 5.68 Ease of ignition (average temperature to ignite mixture): 6.2 Tendency to cake: None. Explosive ability: Cannot be detonated. Percentage: 70% magnesium, 15% potassium perchlorate, 7.5% silicon dioxide, 7.5% polybutadiene Classification: Deflagrating mixture (classified as 1.3G pyrotechnic composition).

- Mua astaxanthin uống có tốt không? Mua ở đâu? 29/10/2018

- Saffron (nhụy hoa nghệ tây) uống như thế nào cho hợp lý? 29/09/2018

- Saffron (nghệ tây) làm đẹp như thế nào? 28/09/2018

- Giải đáp những thắc mắc về viên uống sinh lý Fuji Sumo 14/09/2018

- Công dụng tuyệt vời từ tinh chất tỏi với sức khỏe 12/09/2018

- Mua collagen 82X chính hãng ở đâu? 26/07/2018

- NueGlow mua ở đâu giá chính hãng bao nhiêu? 04/07/2018

- Fucoidan Chính hãng Nhật Bản giá bao nhiêu? 18/05/2018

- Top 5 loại thuốc trị sẹo tốt nhất, hiệu quả với cả sẹo lâu năm 20/03/2018

- Footer chi tiết bài viết 09/03/2018

- Mã vạch không thể phân biệt hàng chính hãng hay hàng giả 10/05/2023

- Thuốc trắng da Ivory Caps chính hãng giá bao nhiêu? Mua ở đâu? 08/12/2022

- Nên thoa kem trắng da body vào lúc nào để đạt hiệu quả cao? 07/12/2022

- Tiêm trắng da toàn thân giá bao nhiêu? Có an toàn không? 06/12/2022

- Top 3 kem dưỡng trắng da được ưa chuộng nhất hiện nay 05/12/2022

- Uống vitamin C có trắng da không? Nên uống như thế nào? 03/12/2022

- [email protected]

- Hotline: 0909977247

- Hotline: 0908897041

- 8h - 17h Từ Thứ 2 - Thứ 7

Đăng ký nhận thông tin qua email để nhận được hàng triệu ưu đãi từ Muathuoctot.com

Tạp chí sức khỏe làm đẹp, Kem chống nắng nào tốt nhất hiện nay Thuoc giam can an toan hiện nay, thuoc collagen, thuoc Dong trung ha thao , thuoc giam can LIC, thuoc shark cartilage thuoc collagen youtheory dau ca omega 3 tot nhat, dong trung ha thao aloha cua my, kem tri seo hieu qua, C ollagen shiseido enriched, và collagen shiseido dạng viên , Collagen de happy ngăn chặn quá trình lão hóa, mua hang tren thuoc virility pills vp-rx tri roi loan cuong duong, vitamin e 400, dieu tri bang thuoc fucoidan, kem chống nhăn vùng mắt, dịch vụ giao hang nhanh nội thành, crest 3d white, fine pure collagen, nên mua collagen shiseido ở đâu, làm sáng mắt, dịch vụ cho thue kho lẻ tại tphcm, thực phẩm tăng cường sinh lý nam, thuoc prenatal bổ sung dinh dưỡng, kem đánh răng crest 3d white, hỗ trợ điều trị tim mạch, thuốc trắng da hiệu quả giúp phục hồi da. thuốc mọc tóc biotin

KHUYẾN MÃI LỚN

KHUYẾN MÃI LỚN Hỗ Trợ Xương Khớp

Hỗ Trợ Xương Khớp Bổ Não & Tăng cường Trí Nhớ

Bổ Não & Tăng cường Trí Nhớ Bổ Sung Collagen & Làm Đẹp

Bổ Sung Collagen & Làm Đẹp Bổ Thận, Mát Gan & Giải Độc

Bổ Thận, Mát Gan & Giải Độc Chăm Sóc Sức khỏe Nam Giới

Chăm Sóc Sức khỏe Nam Giới Chăm Sóc Sức khỏe Nữ Giới

Chăm Sóc Sức khỏe Nữ Giới Chăm sóc Sức khỏe Trẻ Em

Chăm sóc Sức khỏe Trẻ Em Thực Phẩm Giảm Cân, Ăn Kiêng

Thực Phẩm Giảm Cân, Ăn Kiêng Bổ Sung Vitamin & Khoáng Chất

Bổ Sung Vitamin & Khoáng Chất Bổ Tim Mạch, Huyết Áp & Mỡ Máu

Bổ Tim Mạch, Huyết Áp & Mỡ Máu Bổ Mắt & Tăng cường Thị lực

Bổ Mắt & Tăng cường Thị lực Điều Trị Tai Mũi Họng

Điều Trị Tai Mũi Họng Sức Khỏe Hệ Tiêu hóa

Sức Khỏe Hệ Tiêu hóa Chăm Sóc Răng Miệng

Chăm Sóc Răng Miệng Chống Oxy Hóa & Tảo Biển.

Chống Oxy Hóa & Tảo Biển.