-

Thanh toán đa dạng, linh hoạtChuyển khoản ngân hàng, thanh toán tại nhà...

Thanh toán đa dạng, linh hoạtChuyển khoản ngân hàng, thanh toán tại nhà... -

Miễn Phí vận chuyển 53 tỉnh thànhMiễn phí vận chuyển đối với đơn hàng trên 1 triệu

Miễn Phí vận chuyển 53 tỉnh thànhMiễn phí vận chuyển đối với đơn hàng trên 1 triệu -

Yên Tâm mua sắmHoàn tiền trong vòng 7 ngày...

Yên Tâm mua sắmHoàn tiền trong vòng 7 ngày...

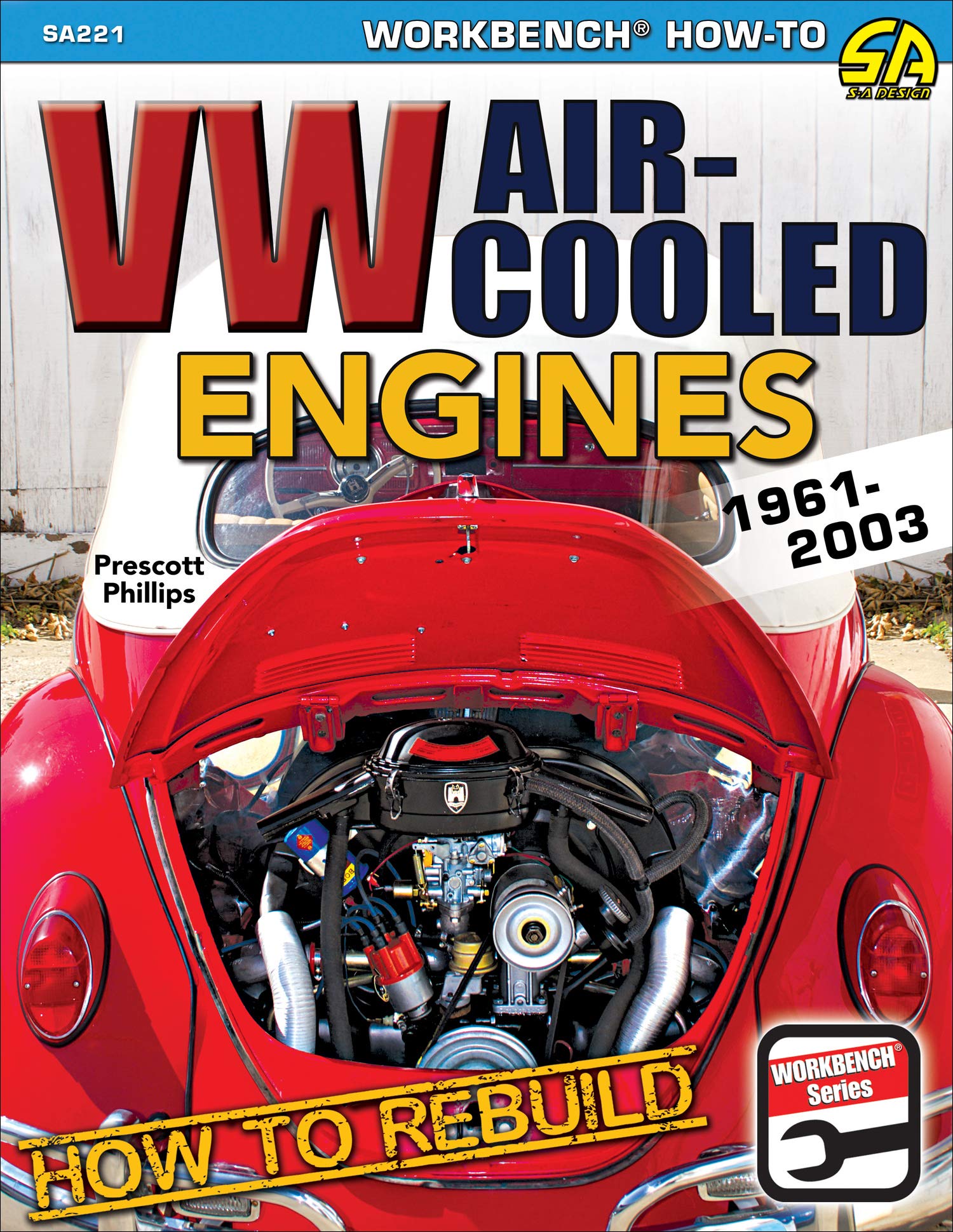

- Publisher:CarTech (August 7, 2019)

- Language:English

- Paperback:144 pages

- ISBN-10:1613254334

- ISBN-13:978-1613254332

- Item Weight:1.1 pounds

- Dimensions:8.5 x 0.25 x 11 inches

- Best Sellers Rank:#231,956 in Books (See Top 100 in Books) #83 in Automotive Engine Mechanics #520 in Do-It-Yourself Home Improvement (Books)

- Customer Reviews:4.8 out of 5 stars 195Reviews

Mô tả sản phẩm

From the Publisher

VW Air-Cooled Engines: How to Rebuild will focus its coverage on the VW Type 1, 2 and 3 engines beginning in the year 1961, when a significant re-design improved the reliability, durability and horsepower of the basic initial design. This book will offer insightful step-by-step captions and color photos for expertly rebuilding an air-cooled engine and will provide in-depth hands-on information for disassembly, inspection, machining, parts selection, pre-assembly, final assembly, installation, and tuning.

Not only will all the procedures for rebuilding be covered in depth, but engine model types, Identification codes, specifications and details will be covered in a manner that will allow the user to source a good later model candidate for rebuilding and help retrofit the modern engine designs into earlier chassis.

Disassembly

This is what it should look like with all the cooling tin removed. All the sheet metal is attached with 6-mm flathead screws. Depending on how complete the engine you have is or what type of vehicle it was previously installed in will determine what sheet metal it has and what it will need when reassembling.

Cleaning & Inspection

To prep an engine case for initial inspection, remove all cam bearings, center main bearings, and six main stud seals. Next, scrape both halves with a razor blade to remove sealer that’s usually baked on.

Machining

Before clamping the head to the Bridgeport mill, it is always a good idea to make sure the valve cover surface is free of burrs and dents. People tend to get a little overzealous when removing the valve covers. The rocker studs should clear the bottom of the T-slot in the table, but double-check to be sure.

Preassembly

Apply a thin coat of silicone sealer to the pushrod tube seals. Note the dark line that runs the length of the tube. That is the seam that is welded together. Make sure that seam faces up when the engine is installed in the car. Periodically, that seam splits and if it faces down you will have a pesky oil leak.

Final Assembly

Here are the necessary components installed in the 1-2 case half: one bearing dowel pin under one center main bearing, three cam bearings, and four lifters with plenty of assembly lube.

Accessories

Install the fuel pump with a 13-mm wrench. Don’t forget the wave washers under the nuts. If the fuel pump seems too high off the base, don’t force it on with the nuts. This indicates that two things may be wrong: either the distributor drive isn’t seated all the way down in the bore or the fuel pump pushrod is the wrong length.

- Mua astaxanthin uống có tốt không? Mua ở đâu? 29/10/2018

- Saffron (nhụy hoa nghệ tây) uống như thế nào cho hợp lý? 29/09/2018

- Saffron (nghệ tây) làm đẹp như thế nào? 28/09/2018

- Giải đáp những thắc mắc về viên uống sinh lý Fuji Sumo 14/09/2018

- Công dụng tuyệt vời từ tinh chất tỏi với sức khỏe 12/09/2018

- Mua collagen 82X chính hãng ở đâu? 26/07/2018

- NueGlow mua ở đâu giá chính hãng bao nhiêu? 04/07/2018

- Fucoidan Chính hãng Nhật Bản giá bao nhiêu? 18/05/2018

- Top 5 loại thuốc trị sẹo tốt nhất, hiệu quả với cả sẹo lâu năm 20/03/2018

- Footer chi tiết bài viết 09/03/2018

- Mã vạch không thể phân biệt hàng chính hãng hay hàng giả 10/05/2023

- Thuốc trắng da Ivory Caps chính hãng giá bao nhiêu? Mua ở đâu? 08/12/2022

- Nên thoa kem trắng da body vào lúc nào để đạt hiệu quả cao? 07/12/2022

- Tiêm trắng da toàn thân giá bao nhiêu? Có an toàn không? 06/12/2022

- Top 3 kem dưỡng trắng da được ưa chuộng nhất hiện nay 05/12/2022

- Uống vitamin C có trắng da không? Nên uống như thế nào? 03/12/2022

- [email protected]

- Hotline: 0909977247

- Hotline: 0908897041

- 8h - 17h Từ Thứ 2 - Thứ 7

Đăng ký nhận thông tin qua email để nhận được hàng triệu ưu đãi từ Muathuoctot.com

Tạp chí sức khỏe làm đẹp, Kem chống nắng nào tốt nhất hiện nay Thuoc giam can an toan hiện nay, thuoc collagen, thuoc Dong trung ha thao , thuoc giam can LIC, thuoc shark cartilage thuoc collagen youtheory dau ca omega 3 tot nhat, dong trung ha thao aloha cua my, kem tri seo hieu qua, C ollagen shiseido enriched, và collagen shiseido dạng viên , Collagen de happy ngăn chặn quá trình lão hóa, mua hang tren thuoc virility pills vp-rx tri roi loan cuong duong, vitamin e 400, dieu tri bang thuoc fucoidan, kem chống nhăn vùng mắt, dịch vụ giao hang nhanh nội thành, crest 3d white, fine pure collagen, nên mua collagen shiseido ở đâu, làm sáng mắt, dịch vụ cho thue kho lẻ tại tphcm, thực phẩm tăng cường sinh lý nam, thuoc prenatal bổ sung dinh dưỡng, kem đánh răng crest 3d white, hỗ trợ điều trị tim mạch, thuốc trắng da hiệu quả giúp phục hồi da. thuốc mọc tóc biotin

KHUYẾN MÃI LỚN

KHUYẾN MÃI LỚN Hỗ Trợ Xương Khớp

Hỗ Trợ Xương Khớp Bổ Não & Tăng cường Trí Nhớ

Bổ Não & Tăng cường Trí Nhớ Bổ Sung Collagen & Làm Đẹp

Bổ Sung Collagen & Làm Đẹp Bổ Thận, Mát Gan & Giải Độc

Bổ Thận, Mát Gan & Giải Độc Chăm Sóc Sức khỏe Nam Giới

Chăm Sóc Sức khỏe Nam Giới Chăm Sóc Sức khỏe Nữ Giới

Chăm Sóc Sức khỏe Nữ Giới Chăm sóc Sức khỏe Trẻ Em

Chăm sóc Sức khỏe Trẻ Em Thực Phẩm Giảm Cân, Ăn Kiêng

Thực Phẩm Giảm Cân, Ăn Kiêng Bổ Sung Vitamin & Khoáng Chất

Bổ Sung Vitamin & Khoáng Chất Bổ Tim Mạch, Huyết Áp & Mỡ Máu

Bổ Tim Mạch, Huyết Áp & Mỡ Máu Bổ Mắt & Tăng cường Thị lực

Bổ Mắt & Tăng cường Thị lực Điều Trị Tai Mũi Họng

Điều Trị Tai Mũi Họng Sức Khỏe Hệ Tiêu hóa

Sức Khỏe Hệ Tiêu hóa Chăm Sóc Răng Miệng

Chăm Sóc Răng Miệng Chống Oxy Hóa & Tảo Biển.

Chống Oxy Hóa & Tảo Biển.